SOFT Annealed Black Iron Baling Wire-100 t x 3.40 mm Outside Diameter black annealed baling wire (1000 kgs / roll)

Black annealed wire as baling tie is mainly used in agriculture for binding hay, cottons and other materials. Also used in building and construction. Major processing steps involved for Black or Dark Annealed Baling Wire include wire drawing, acid washing, rust removing and oxygen free annealing.

The black annealed wire is made of low carbon steel wire rod material Q195 and finished with oil to avoid getting rust. Iron wire through annealing is soft for processing and baling uses. It has high strength and good stretching resistance.

Forms of Supply: Soft annealed baling tie can be easily processed into various forms: coil wire, spool wire, big package wire, looped wire, straightened cut wire and

U type wire.

Features:

1. Steel wire through annealing has flexible and high tensile strength;

2. Low cost and economy;

3. Easy to handle and further process;

4.Continuous coiling and uniform diameters;

5. High stretching resistance.

Annealed Wire Specification:

(1). Material: Q195, Low carbon steel wire

(2). Element composition is as follows: C≤0.07; S≤0.023; Si≤0.09; Mn≤0.32; P≤0.025.

(3). Diameter: 0.30mm-4.19mm

(4). Tensile strength: 300-450N/mm2

(5). Elongation: 10%-25%

Producing Process:

Annealed baling wire is processed from low carbon raw materials Q195 through wire drawing and annealing process. Annealing is to reduce the tensile strength of steel wire. The stove is solid and built with red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Heat Treatment Range is from 70 ℃ to 90 ℃. The tensile strength is 400N~600N. Standard coil is10kg ,25kg ,50kg and 100kg.

Soft annealing of iron wire reduces internal stress and reduces the amount of defects like dislocations. The wire annealing reduces the disadvantages of a high degree of cold processing and prepares the iron wire for future production steps. Reduced hardness makes processes like milling, wire drawing and wire looping, wire fabrication to ideal forms easier to handle and reduces the risk of crack growth.

With anvanced anaerobic annealed line, Aimlong can produce high quality annealed wire of all specifications and strength.

Black annealed baling wire, oiled, Rm=320-400 N/mm2, in rosette coils of 500 kg;

d=3,1 mm. 22 To (one FCL)

d=3,4 mm. 22 To (one FCL)

Packing:

Weight:1kg-800kg/coil

MOQ:100 kg

Packaging DetailsBinding wire:

1. Inside with plastic film and outside with hessian

2. Inside with plastic film and outside with woven bag

3.In wooden case and as your inquiry

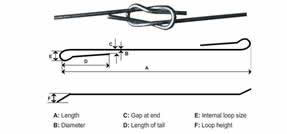

Baling wire with loops at the end.

straps of 3 mm

Length 3550 mm

Strength Rm=1400-1700 N/mm²

We offer the following annealed iron baling wire products, See product images listed below.

Annealed Wire Coils -Dark annealed steel to use as baling wire Ø1.625mm

Black Steel Single Looped Wire

Baling Wire (Black Annealed Wires) Roll

Diameter: 1.6 ± 3%, Weight: 30kg ± 3%

3,4 mm endless baling wire (in 1000 Kg Reels):

black annealed iron wire

Diam. 3,40 EE

Resistance 30/40 Kg/mtnq

Elongation 30 %

Rosettes 1000 Kg each+oiled

Outside diameter M 800

inside diameter mm 450

Height mm 800

Strapped with four handling rings

Packed with polyethilene fiIm

suitable without former

on pallet

Galvanised Iron Wire Continuous Coils Rolls

Construction Coil Tying Wire

Annealed Wire Bundles

12 gauge 15' baling wire

U Type Wire

for Bale Tying

| Black Annealed Steel Wire for Baling | |||

| Wire Gauge | SWG(mm) | BWG(mm) | Metric(mm) |

| 8# | 4.06 | 4.19 | 4.00 |

| 9# | 3.66 | 3.76 | - |

| 10# | 3.25 | 3.40 | 3.50 |

| 11# | 2.95 | 3.05 | 3.00 |

| 12# | 2.64 | 2.77 | 2.80 |

| 13# | 2.34 | 2.41 | 2.50 |

| 14# | 2.03 | 2.11 | - |

| 15# | 1.83 | 1.83 | 1.80 |

| 16# | 1.63 | 1.65 | 1.65 |

| 17# | 1.42 | 1.47 | 1.40 |

| 18# | 1.22 | 1.25 | 1.20 |

| 19# | 1.02 | 1.07 | 1.00 |

| 20# | 0.91 | 0.89 | 0.90 |

| 21# | 0.81 | 0.813 | 0.80 |

| 22# | 0.71 | 0.711 | 0.70 |